Selar machine

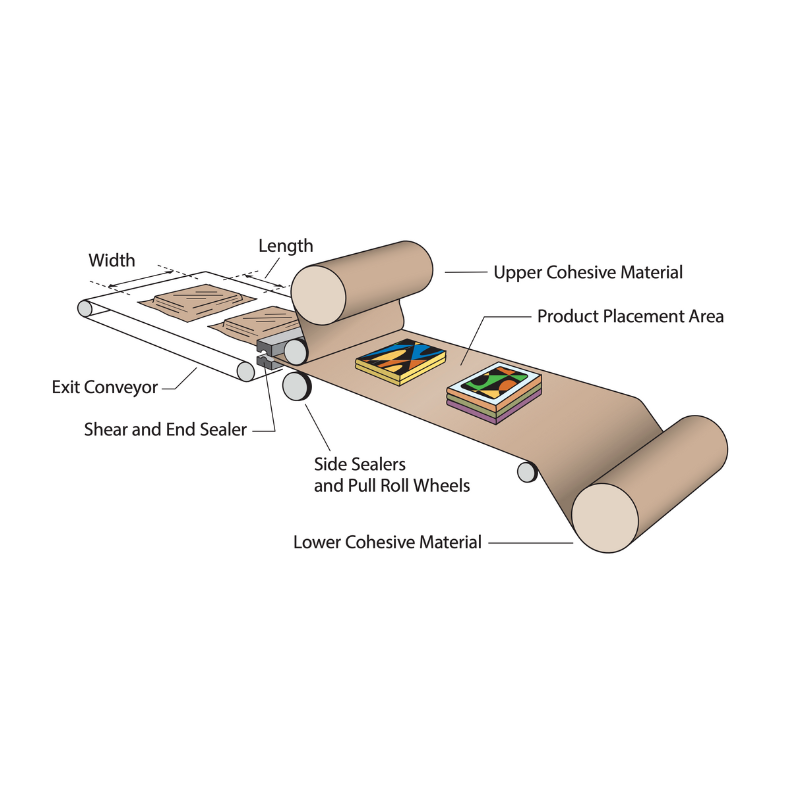

The Selar machine is an advanced packaging solution that is ideal for efficiently packaging a wide range of products. This machine is designed to save costs and reduce labor by automating the packaging process. With its flexible settings, users can quickly adjust the machine to accommodate different product sizes, making it suitable for various applications.

The Selar machine is particularly well-suited for industries such as automotive, medical products, building materials, and light manufacturing. The machine offers different models, each designed for specific packaging needs, varying in material size and product depth.

Key features of the Selar machine:

- Flexibility: Easy adjustment of the machine to package different product sizes.

- Cost-saving: Reduces labor costs by automating the packaging process.

- Durability: Designed for long-term use, ideal for businesses that need to package regularly.

Different models of the Selar machine:

Selar machine model 1

- Maximum product depth: 6.35 cm

- Maximum material size: 30.48 cm

- Minimum material size: 10 cm x 15 cm

This model is suitable for smaller products and is ideal for businesses that frequently require small packaging.

Selar machine model 2

- Maximum product depth: 12.7 cm

- Maximum material size: 45.72 cm

- Minimum material size: 10 cm x 15 cm

This model is suitable for medium-sized products and offers more flexibility for various applications.

Selar machine model 3

- Maximum product depth: 12.7 cm

- Maximum material size: 60.96 cm

- Minimum material size: 10 cm x 15 cm

Ideal for larger products that need extra protection, with the ability to use larger materials.

Selar machine model 4

- Maximum product depth: 12.7 cm

- Maximum material size: 20.32 cm

- Minimum material size: 10 cm x 15 cm

This model offers a more specific option for packaging smaller yet larger products than model 1.

Selar machine model 5

- Maximum product depth: 20.32 cm

- Maximum material size: 91.44 cm

- Minimum material size: 10 cm x 15 cm

Benefits of the Selar machine:

- Flexibility: The Selar machine can be easily adjusted to accommodate different product sizes. This allows for efficient packaging of a wide range of products, from small components to larger items, without wasting time on adjustments.

- Cost savings: By automating the packaging process, the Selar machine reduces the labor required, resulting in lower labor costs and faster production times.

- Increased efficiency: The machine is designed to work quickly and accurately, enabling businesses to increase their production capacity while maintaining consistent packaging quality.

- Durability: Built for long-term use, the Selar machine is a cost-effective investment for businesses that need to package regularly. Its robust design ensures it lasts even under heavy use.

- Ease of operation: The machine is user-friendly, with intuitive settings that allow for quick product changes, minimizing operational downtime.

- Custom packaging: The Selar machine is compatible with various packaging materials and can be tailored to protect a wide range of products, from delicate to heavy items.

Product benefits

Benefits of the Selar machine:

- Flexibility: The Selar machine can be easily adjusted to accommodate different product sizes. This allows for efficient packaging of a wide range of products, from small components to larger items, without wasting time on adjustments.

- Cost savings: By automating the packaging process, the Selar machine reduces the labor required, resulting in lower labor costs and faster production times.

- Increased efficiency: The machine is designed to work quickly and accurately, enabling businesses to increase their production capacity while maintaining consistent packaging quality.

- Durability: Built for long-term use, the Selar machine is a cost-effective investment for businesses that need to package regularly. Its robust design ensures it lasts even under heavy use.

- Ease of operation: The machine is user-friendly, with intuitive settings that allow for quick product changes, minimizing operational downtime.

- Custom packaging: The Selar machine is compatible with various packaging materials and can be tailored to protect a wide range of products, from delicate to heavy items.

Description

The Selar machine is an advanced packaging solution that is ideal for efficiently packaging a wide range of products. This machine is designed to save costs and reduce labor by automating the packaging process. With its flexible settings, users can quickly adjust the machine to accommodate different product sizes, making it suitable for various applications.

The Selar machine is particularly well-suited for industries such as automotive, medical products, building materials, and light manufacturing. The machine offers different models, each designed for specific packaging needs, varying in material size and product depth.

Key features of the Selar machine:

- Flexibility: Easy adjustment of the machine to package different product sizes.

- Cost-saving: Reduces labor costs by automating the packaging process.

- Durability: Designed for long-term use, ideal for businesses that need to package regularly.

Different models of the Selar machine:

Selar machine model 1

- Maximum product depth: 6.35 cm

- Maximum material size: 30.48 cm

- Minimum material size: 10 cm x 15 cm

This model is suitable for smaller products and is ideal for businesses that frequently require small packaging.

Selar machine model 2

- Maximum product depth: 12.7 cm

- Maximum material size: 45.72 cm

- Minimum material size: 10 cm x 15 cm

This model is suitable for medium-sized products and offers more flexibility for various applications.

Selar machine model 3

- Maximum product depth: 12.7 cm

- Maximum material size: 60.96 cm

- Minimum material size: 10 cm x 15 cm

Ideal for larger products that need extra protection, with the ability to use larger materials.

Selar machine model 4

- Maximum product depth: 12.7 cm

- Maximum material size: 20.32 cm

- Minimum material size: 10 cm x 15 cm

This model offers a more specific option for packaging smaller yet larger products than model 1.

Selar machine model 5

- Maximum product depth: 20.32 cm

- Maximum material size: 91.44 cm

- Minimum material size: 10 cm x 15 cm